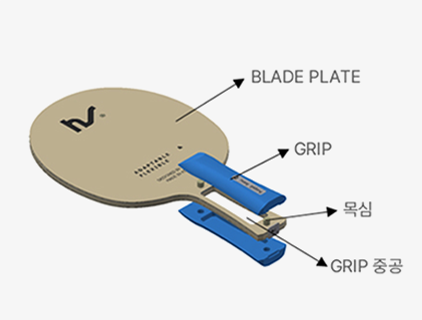

GRIP

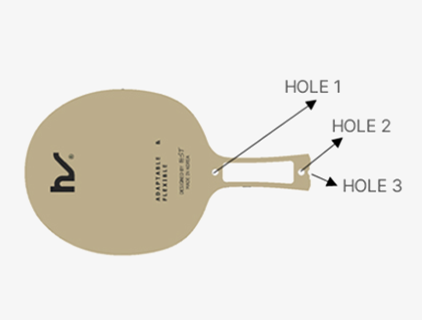

1. Precision Symmetry in Machining

The central hole (Figure 3) serves as a reference point for all processing.

It ensures perfect lateral symmetry.

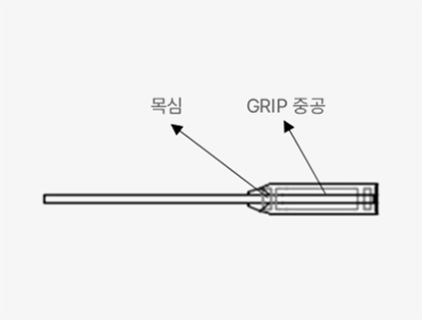

2. Accurate and secure grip assembly

Grips and blades are aligned using holes, and dowels are inserted to strengthen them.

adhesion and impact resistance.

3. Optimized Weight Distribution

Empty space inside the grip (Figure 1) moves the center of gravity towards the head.

Improves swing power. You can adjust the hollow size for the desired performance.

4. Enhanced Grip Bonding

Even if the joint area is reduced due to empty space (Figures 1 and 2), Dowell prevents grip separation (Figures 1 and 2)

5. Patent Technology

This manufacturing method is protected under Korean Patent No. 10-2719263.

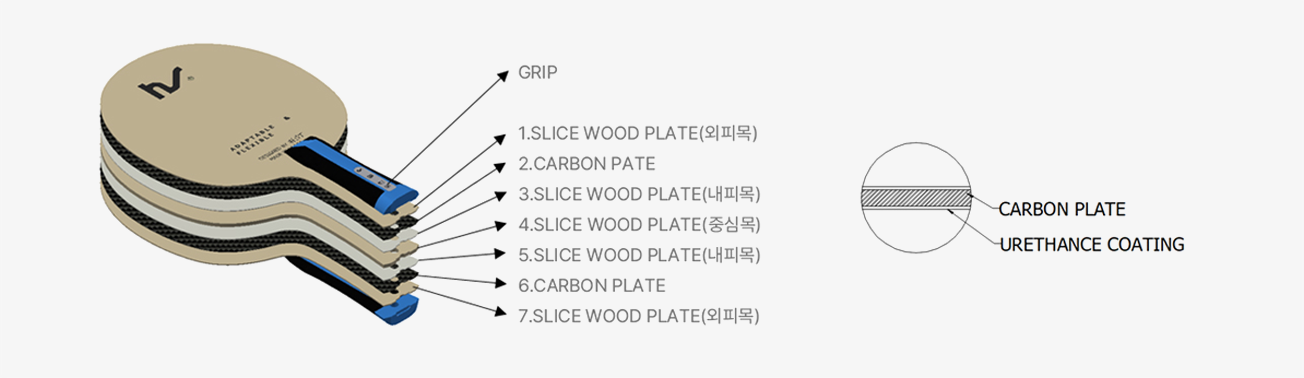

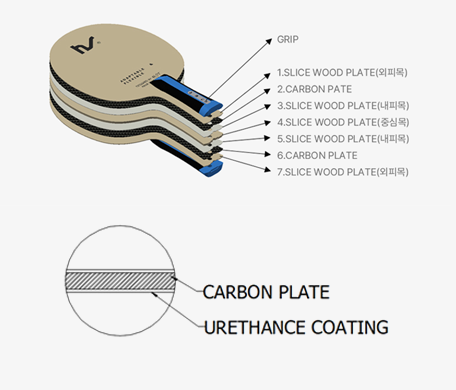

RACKET BLADE

1. Performance Adjustment

The elasticity of carbon is finely tuned with a urethane coating to meet the needs of different players.

2. Overcoming Limitations

Unlike conventional methods that require complex material combinations, the coating regulates the tension directly and efficiently.

3. Efficient Development

By selecting core materials and applying urethane coating, fine tension control is possible, saving time and precise performance adjustments.

4. Patent status

This coating and bonding method is currently patent-pending.