Hinoki

It is a species of wood with many differences in characteristics depending on the direction of the grain. It is a wood with great elasticity in the vertical grain and a soft, ball-holding feel in the horizontal grain, making it very two-sided.

At the same time, it boasts the advantage of being lighter than other woods, which is why it's used in penholder rackets.

Japanese Hinoki, with its dense growth rings and over 200 years old, is the ideal wood for making fine penholder rackets.

Due to these characteristics, it is also processed into sliced plates and used as the outer and inner skins for shakehand rackets.

A disadvantage is its weak physical properties, requiring caution when handling rackets.

Koto

It's a broadleaf wood with high density, resulting in excellent elasticity and a higher weight than other woods, making it primarily used as the outer covering for rackets. Its strong physical properties also make it easy to maintain the surface of the racket.

Its high resilience makes it particularly suitable for players who prefer smashing and high-speed hits rather than drive control and spin. It's primarily used as the outer covering for shakehand rackets.

While it has a neutral character, its excellent workability makes it a popular choice for table tennis rackets. Its ability to be sliced thin also makes it a valuable option.

Limba

Limba is a broadleaf wood with a low density, lightweight, and soft feel. It also possesses some elasticity, making it ideal for the outer shell of shakeholder inner-type rackets, which prioritize spin and control.

The striking sensation is similar to a single plate, cradling the ball.

Due to these unique sensory advantages, Limba has been widely used in the surface layer of Stigga, a trend that continues to be widely adopted in current DHS products. However, its weak physical properties require careful surface maintenance.

Spruce

Hinoki cypress is a material that possesses the elasticity and soft grip characteristic of hinoki. Its stronger elasticity than hinoki cypress makes it a popular choice for carbon fiber replacement and as a lining material, making it ideal for making resilient rackets. It's also a good alternative to carbon fiber in plywood rackets.

Examples of its use include Stiga's Offensive Classic and DHS's Wang Liqin and Wang Nan rackets. Numerous other brands use it to create fast plywood rackets. Nexi used it in its early Dexter product.

Ayous

This wood has a low density, making it light, soft, and soft, with low elasticity. Its light weight makes it a popular choice for the core of rackets.

Its soft, enveloping feel makes it suitable for use as the outer wood for inner rackets. However, its low elasticity requires increased elasticity during production. HST utilizes patented bonding technology to address this issue, allowing players to achieve the desired elasticity.

Due to its weak physical properties, careful surface maintenance is necessary when using it as an outer wood.

Kiri

Its extremely low density makes it lightweight and its elastic modulus is very low, making it often used in center necks to reduce racket weight.

It is not commonly used in outer or inner necks.

-

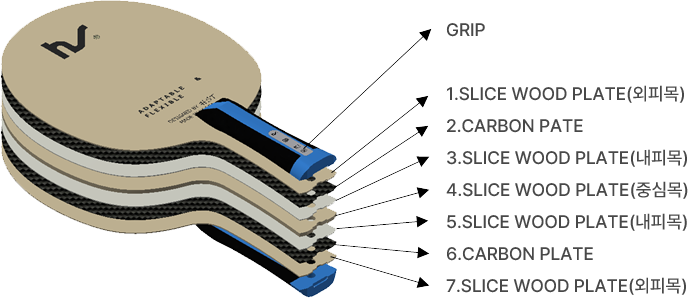

FOCALA

- ㆍ

- KOTO 0.55~0.6mm

- ㆍ

- CARBON 0.4mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- AYOUS (vertical) 3.0mm~3.1mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- CARBON 0.4mm

- ㆍ

- KOTO 0.55mm~0.6mm

The Focala is an outer-style blade with the koto placed at the outermost edge. The core is made up of three layers of ayuse, woven horizontally and vertically.

This method enhances the strength of the central layer, while the carbon composite material is used just outside of it to reinforce the overall strength of the center.

The koto layer is then placed just outside of the core to ensure that this enhanced strength is directly transferred to the ball.

-

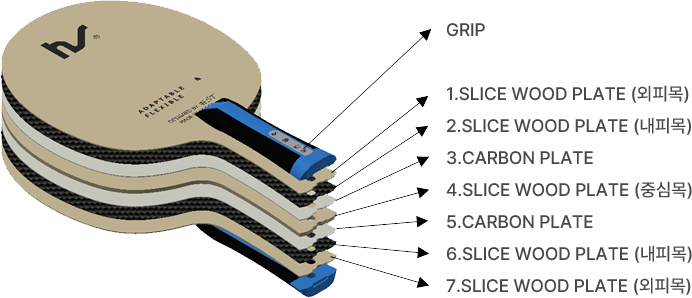

ROTELA

- ㆍ

- LIMBA 0.55~0.6mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- ALC 0.4mm

- ㆍ

- AYOUS (vertical) 3.0~3.1mm

- ㆍ

- ALC 0.4mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- LIMBA 0.55~0.6mm

The Rotella's overall structure is quite similar to the W968 racket. However, the bonded glue layers differ, resulting in a different feel.

The top layer, Limba, provides a snug, hugging sensation, while the Ayuse, located beneath, catches the ball with a single point and provides support.

Many Nexi products utilize an Ayuse layer directly beneath the top layer.

-

EIGER

- ㆍ

- Kiso Hinoki 1mm

- ㆍ

- ALC 0.4mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- KIRI 2.6mm

- ㆍ

- AYOUS (horizontal) 0.6mm

- ㆍ

- ALC 0.4mm

- ㆍ

- Kiso Hinoki 1mm

The EIGER is a traditional Hinoki carbon racket, with Hinoki placed on the outermost layer.

The Kiri layer in the center layer further reduces weight and adds agility.

Please refer to the structure of the three rackets above to decide on the materials for the surface and center layers.

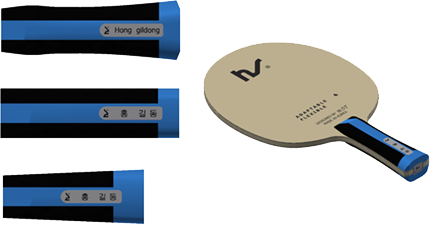

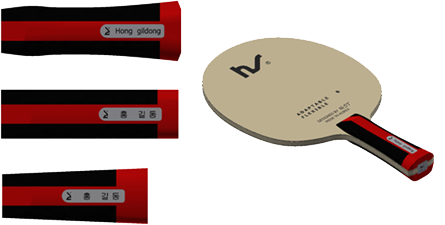

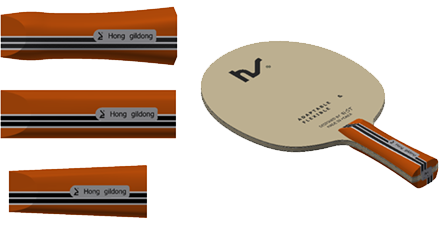

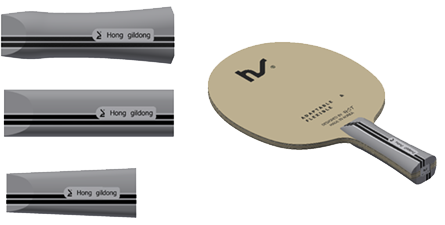

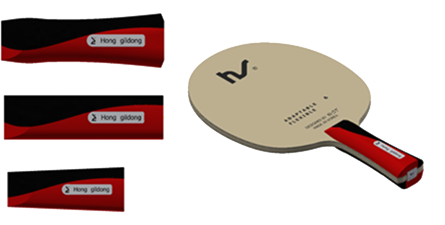

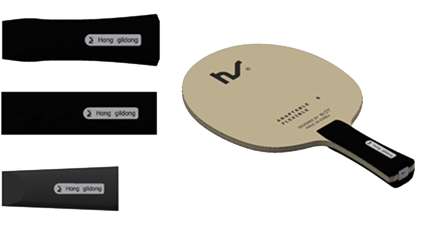

홍 길 동

홍 길 동 Hong gildong

Hong gildong HONG G.D

HONG G.D